Resource Center System

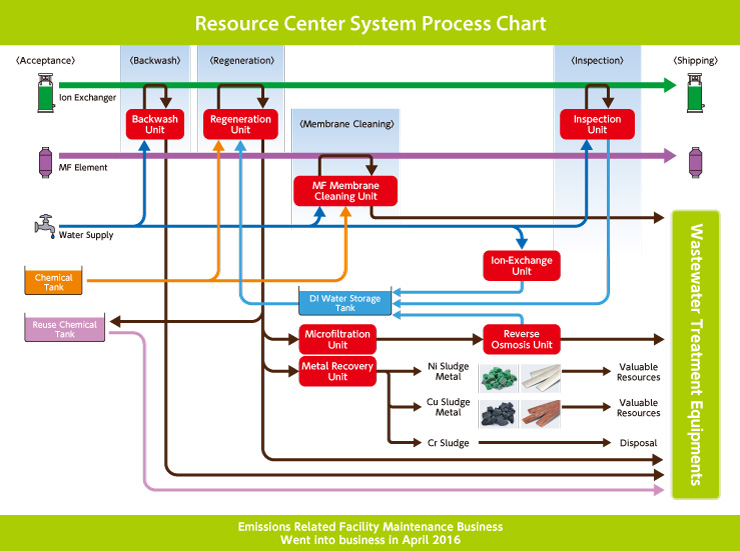

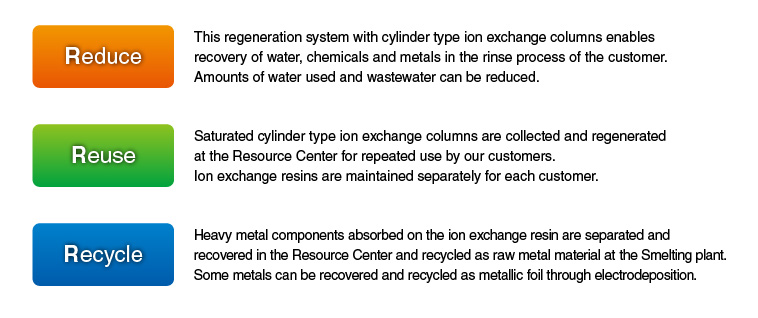

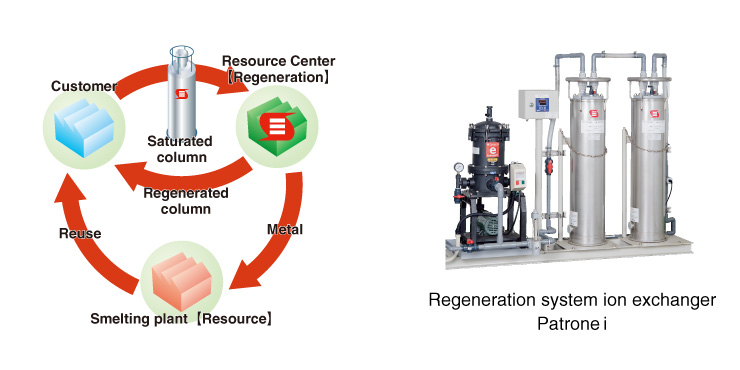

SANSHIN's resource center system is used to collect metals, chemicals, water and energy disposed of at each line to realize resource recycling with a centralized individual recovery process.

Achievements of the Resource Center System

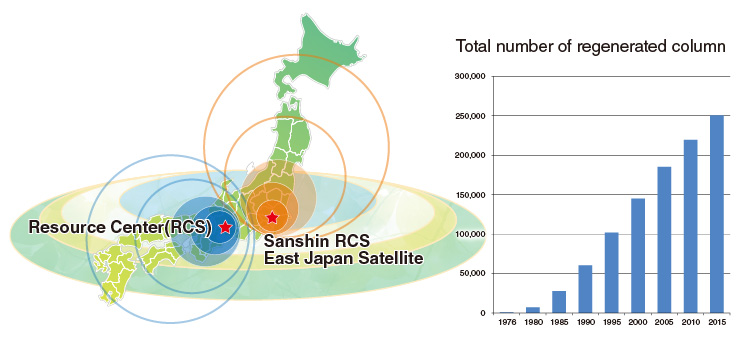

The Resource Center was established in 1976 in Inuyama factory for recovery and recycle of metals contained in wastewater during plating process. We have been serving users throughout Japan by collecting and regenerating over 6,000 cylinder type ion exchange columns a year, counting over 250,000 columns in total by the end of March 2016.

Furthermore, we established Sanshin RCS East Japan Satellite in Tokyo in 2016, in order to achieve greater efficiency in the regeneration of ion exchange columns.

A Brief History of the Resource Center System

- 1971. 8

- SANSHIN's existing research involving "industrial experiments on plating wastewater treatment for the recycling of both chemicals and water" was designated as the Ministry of International Trade and Industry's important technological development issues in 1971.

- 1976. 4

- Established the Resource Center at Inuyama factory, and began sales of the cylinder type ion exchanger "Patrone i", and launched our regeneration business.

- 1983. 5

- Received Tokai Chemical Industry Association Award.

- 1988. 5

- Received Tokai Chemical Industry Association Award.

- 2007. 2

Received Silver Prize of Aichi Environment Award.

Received Silver Prize of Aichi Environment Award.- 2010. 4

- Received "2009 pioneering and efficient recycle business" certification from Aichi prefecture, and also started a high-functionality resource recovery system business.

- 2010. 7

- Approved as Aichi Eco-Town facility.

- 2012. 11

Received President Prize of the Japan Environmental Management Association for Industry at Resources Recycling Technology System Awards Ceremony.

Received President Prize of the Japan Environmental Management Association for Industry at Resources Recycling Technology System Awards Ceremony.- 2016. 4

- Received "2015 pioneering and efficient emissions related facility maintenance business" certification from Aichi prefecture, and also started an enhanced resource recovery system business.

- 2016. 5

Selected as "the most active small and medium-sized enterprises 300 in 2016" from the Ministry of Economy, Trade and Industry.

Selected as "the most active small and medium-sized enterprises 300 in 2016" from the Ministry of Economy, Trade and Industry.- 2016.11

- We established Sanshin RCS East Japan Satellite in Tokyo as a new base for collecting regenerating ion exchange columns.

Sanshin RCS East Japan Satellite

Sanshin RCS East Japan Satellite

Click the image to enlarge.

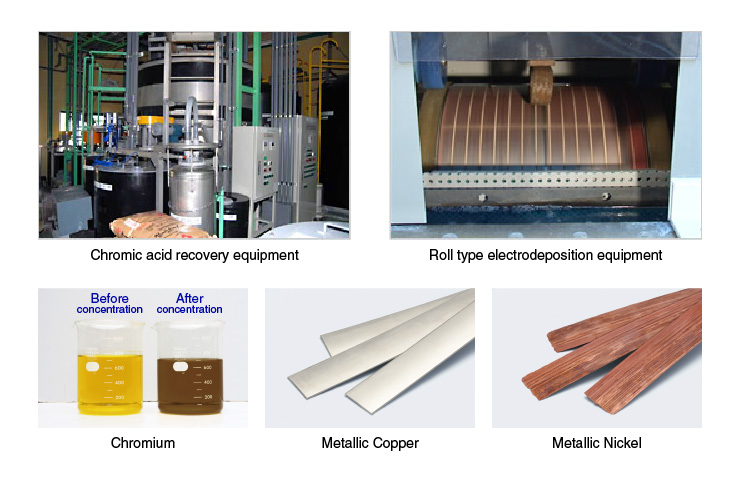

At the Resource Center, with functionality further improved , chromic acid elution is concentrated and purified to acceptable values for resource recycling using chromic acid recovery equipment. Furthermore, we have started to recover and recycle copper and nickel, thereby improving resource recovery efficiency and reducing the amount of waste. (copper and nickel had previously been converted to sludge and recycled at the Smelting Plant as metal foil using a roll type electrodeposition equipment.)

We have reduced the overall amount of chemicals used by recycling some of the wasted acid and alkali from the regeneration chemicals as wastewater treatment chemicals. In addition, we have reduced the amount of water used by desalinating some of the wastewater and reusing it as service water.